PRODUCTS

600PLUS with ALTIBN coating - Economy Series

Product Number:P-SE

█Feature: ①Speed Tiger End Mills Type: Square, Ball Nose, Corner Radius, Miniature, Long Flute, Long Neck, Long Shank, Taper Flute, Pencil Neck, Finishing, Roughing...②HIGH PERFORMANCE FOR HARD MATERIALS - Cutter is made of Micro Grain Carbide that is very tough, resists wear and offers high cutting performance ③HIGH-QUALITY - Flutes ground by a world-class ISO-9001 Factory; Great performance at a competitive price

█Application: GENERAL APPLICATION CUTTER - Speed Tiger 600PLUS carbide tools excel at working carbon steels (~HB225), alloy steels (HB225~325), pre-hardened steels (up to HRC45), hardened Steels (HRC40~45), cast iron.

-

Features

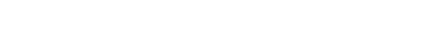

- Maximized rigidity, and chip removals are greatly improved due to special geometric design and reinforced design in cutting edges against chipping at corners.

- Excellent performance of anti-vibration and noise.

- High hardness-used coating, effectively improves tool life and finishes.

Cutting Performance

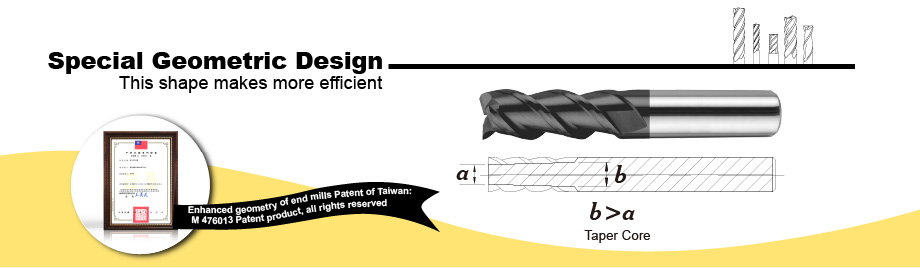

Coating Options

Speed Tiger is not only the largest cutting tools manufacturer, but also the first one that combined milling cutter coating technology in Taiwan. We provide a variety of coating types for different application, you could easily choose the most suitable coating for your work. For detailed coating information, please refer to next tab.

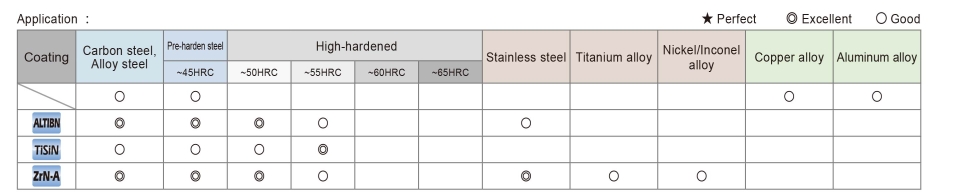

Package & Shipping

Delivery :

Generally, it is 5-7 days if the goods are in stock.

It is 15-20 days if the goods are not in stock, it is according to quantity.

https://www.speedtigertools.com/contact/ -

ALTIBN Coating

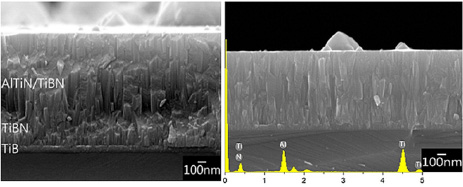

Coating Structural Analysis-SEM

Normal Temperature Mechanical Analysis

In normal temperature mechanical analysis,the performance of AlTiBN is superior to AlTiN in hardness, wear rate and coating roughness.Hardness (Hv) Impact of Diameter Lc2-Lc1 Wear Rate Roughness (µm) AlTiN 3672 305(um) 8.28N 6.49x10-6 0.233 AlTiBN 4088 280.9(um) 17.6N 5.11x10-6 0.166

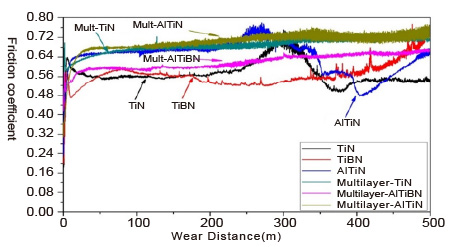

The Oxidation Wear of 700°C

Fiction Coefficient Wear Distance Wear rate TiN 0.5662 316.3 6.4x10-6 TiBN 0.5664 281.2 5.69x10-6 AlTiN 0.6402 281.4 4.97x10-6 Multi-TiN 0.686 277.4 4.82x10-6 ALTIBN 0.618 281.8 4.66x10-6 Mult-ALTiN 0.7014 290.1 5.5x10-6

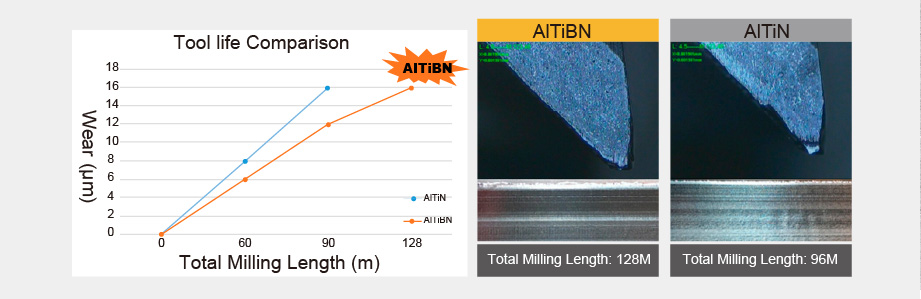

Tool Life Comparison and Cutting Edges

Milling Type Side Milling Feed Rate 1082mm/min Work Piece S45C Depth of Cut ap=20 ae=1.2 Tool Size 10mm x 30 x 75L Coolant Way Air Rotation Speed 3183 rpm CNC Machine CNC YCM FV102A -

Specification Download

Cutting Condition Download

Type Mode Flutes Diameter Photo Miniature Square P-MIE 2 0.2mm~3mm

Square (35°) P-SSE,P-MSE,P-SE 2 / 4 1mm~20mm

Square (45°) P-MPE,P-PE 3 / 4 1mm~20mm

Long Shank Square P-SLE, P-MLE 2/4 6mm~12mm

Long Flute Square P-LET 2/4 1mm~20mm

Long Neck Square P-LNT 2 0.5mm~4mm

Roughing Square P-NTA 3/4 4mm~20mm

Roughing Square P-XTA 3/4 4mm~20mm

Taper Square P-TTA 2 0.5mm~10mm

Taper Long Flute Square P-LTTA 2 1mm~6mm

Miniature Ball Nose P-MIB 2 0.15R~3R

Ball Nose P-SSB,P-MSB,P-SB 2 /4 0.5R~10R

Long Shank Ball Nose P-SL,P-MLB,P-LLB,P-XLB 2 0.5R~8R

Long Neck Ball Nose P-LNBT 2 0.25R~2R

Pencil Neck Ball Nose P-PBTA 2 0.5R~4R

Taper Ball Nose P-TBTA 2 0.5R~1.5R

Corner Radius P-RTA 2 /4 1mm~12mm

Long Shank Corner Radius P-LRTA 2 /4 3mm~12mm

-

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No. 9, Gongyequ 35th Rd., Xitun Dist., Taichung City 407021, Taiwan (R.O.C.)

Worldwide Sales Network

Worldwide Sales Network

● Social Media