PRODUCTS

ALC Carbide Drill For Aluminum Application 5xD 8xD

Product Number:5ALC, 8ALC - 5xD & 8xD Carbide Drill For Aluminum Alloy - With Coolant Hole , Size Range: 3mm~12mm , Point Angle: 130°

█Features: ①Double margin- the second margin also has a cutting edge - Achieves smooth surface of drilling and allow high precision straight cutting. ②High rigidity design, and the room of chip removals greatly improved. ③Improved the margin top position, to advance the drilling precision. █Application: Cooper alloy, Aluminum alloy

-

►5AL ►5ALC ►8ALC - With Coolant Hole

♦Size Range: Ø3-12mm

♦Point Angle: 130º

Features

1. Double margin- the second margin also has a cutting edge.

- Achieves smooth surface of drilling.

- Allow high precision straight cutting.

2. High rigidity design, and the room of chip removals greatly improved.

3. Improved the margin top position, to advance the drilling precision.

Application

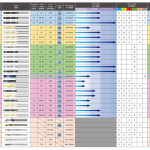

◎ Excellent ○ GoodITEM Carbon steel,

Alloy steelPre-harden steel

~45HRHigh-hardened

~50HRCStainless steel Cast iron Cooper alloy Aluminum alloy Titanium alloy Nickel/

Inconel alloy5AL ◎ ◎

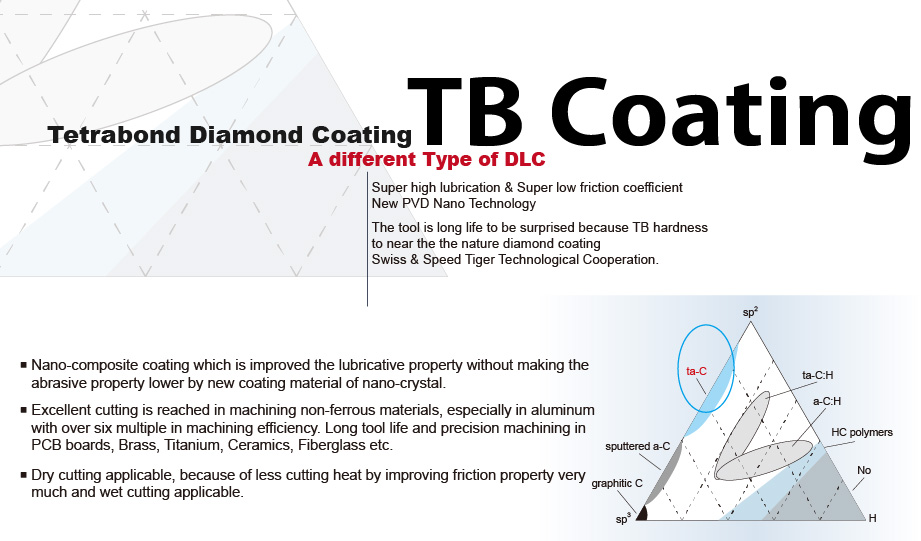

CVD Coating (TB)  Super high lubrication & Super low friction coefficientNew PVD Nano TechnologyThe tool is long life to be surprised because TB hardness to near the nature diamond coatingSwiss & Speed Tiger Technological Cooperation.

Super high lubrication & Super low friction coefficientNew PVD Nano TechnologyThe tool is long life to be surprised because TB hardness to near the nature diamond coatingSwiss & Speed Tiger Technological Cooperation.

- Nano-composite coating which is improved the lubricative property without making the abrasive property lower by new coating material of nano-crystal.

- Excellent cutting is reached in machining non-ferrous materials, especially in aluminumwith over six multiple in machining efficiency. Long tool life and precision machining in PCB boards, Brass, Titanium, Ceramics, Fiberglass etc.

- Dry cutting applicable, because of less cutting heat by improving friction property very much and wet cutting applicable.

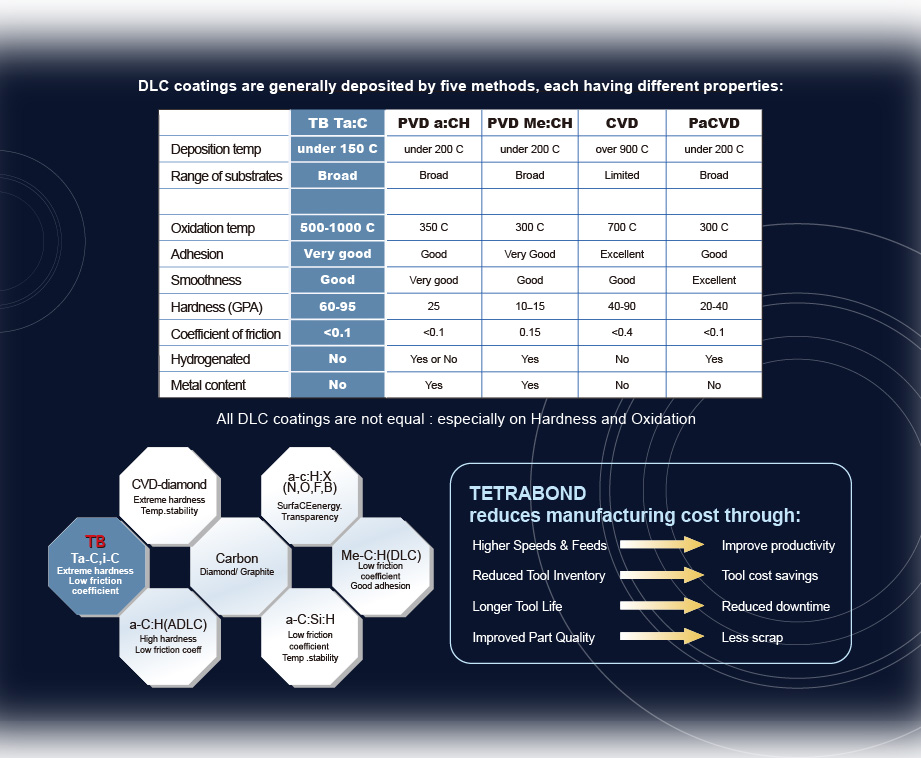

TETRABOND reduces manufacturing cost through:

Higher Speeds & Feeds ➜ Improve productivity

Reduced Tool Inventory ➜ Tool cost savings

Longer Tool Life ➜ Reduced downtime

Improved Part Quality ➜ Less scrap

TETRABOND is an excellent choice for machining non-ferrous materials such as:

High silicon content aluminium alloys

Aluminium magnesium matrix materials

Titanium 6Al4V

Epoxy resins

Fibreglass and composites

Plastic

Graphite

Brass and bronze

Ceramics

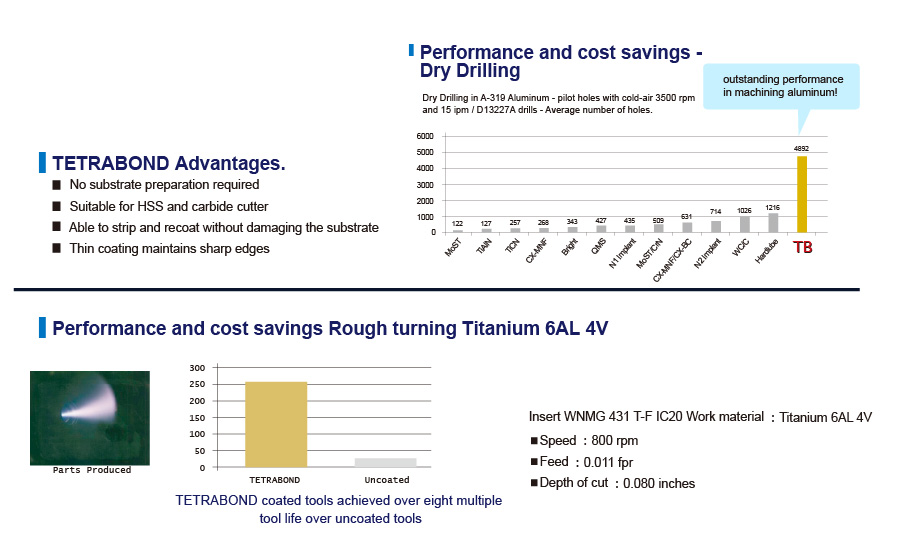

TETRABOND Advantages.- No substrate preparation required

- Suitable for HSS and carbide cutter

- Able to strip and recoat without damaging the substrate

- Thin coating maintains sharp edges

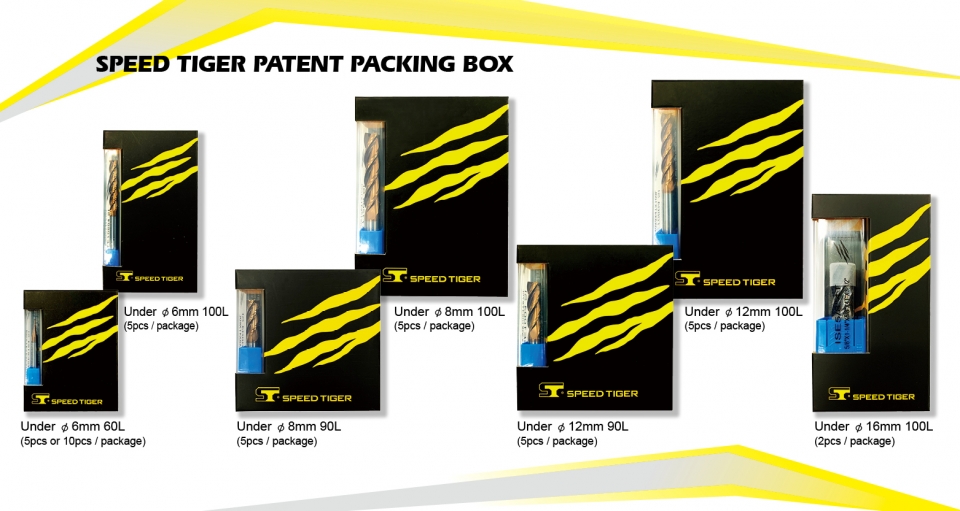

Package & Shipping

Delivery :

Generally, it is 5-7 days if the goods are in stock.

It is 15-20 days if the goods are not in stock, it is according to quantity.

https://www.speedtigertools.com/inquiry/

The Guide to Buying Carbide Drill Bits, Choose the right one for your job! -

Specification Download

Cutting Condition Download

►5AL- without coolant hole ►5ALC & 8ALC- with coolant holeApplication Mode Photo Coolant Hole Helix Angle Point Angle Coating Diameter Aluminum alloy 5AL

X 20° 135° TB

Uncoated3.0mm~12.0mm Aluminum alloy 5ALC

O 15~20° 140° TB

Uncoated3.0mm~12.0mm Aluminum alloy 8ALC

O 15~20° 140° TB

Uncoated3.0mm~12.0mm -

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No. 9, Gongyequ 35th Rd., Xitun Dist., Taichung City 407021, Taiwan (R.O.C.)

Worldwide Sales Network

Worldwide Sales Network

● Social Media

-