SOLUTIONS

Knowledge

What Are the Benefits of Using a Shrink-fit Machine and Shrink-fit System?

What Are the Benefits of Using a Shrink-fit Machine and Shrink-fit System?

This article introduces the three major advantages of using a shrink-fit machine, compares shrink-fit tool holders with collet tool holders, and recommends a shrink-fit machine that can help you save money, reduce processing time, and maximize your return on investment.

You will learn useful knowledge of using a Shrink-fit System.

- Introduction to Shrink-fit Machines and Shrink-fit Tool Holders

- Three Major Benefits of Using a Shrink-fit Machine

- Comparison of Shrink-fit Tool Holders: Pros and Cons

- How to Smartly Choose a Shrink-fit Machine?

- Recommended Shrink-fit Machine – ST3500

- ST3500 Main Applications & How to Use

- FAQs: Shrink-fit Machines & Shrink Fit Tool Holders

Introduction to Shrink-fit Machines and Shrink-fit Tool Holders

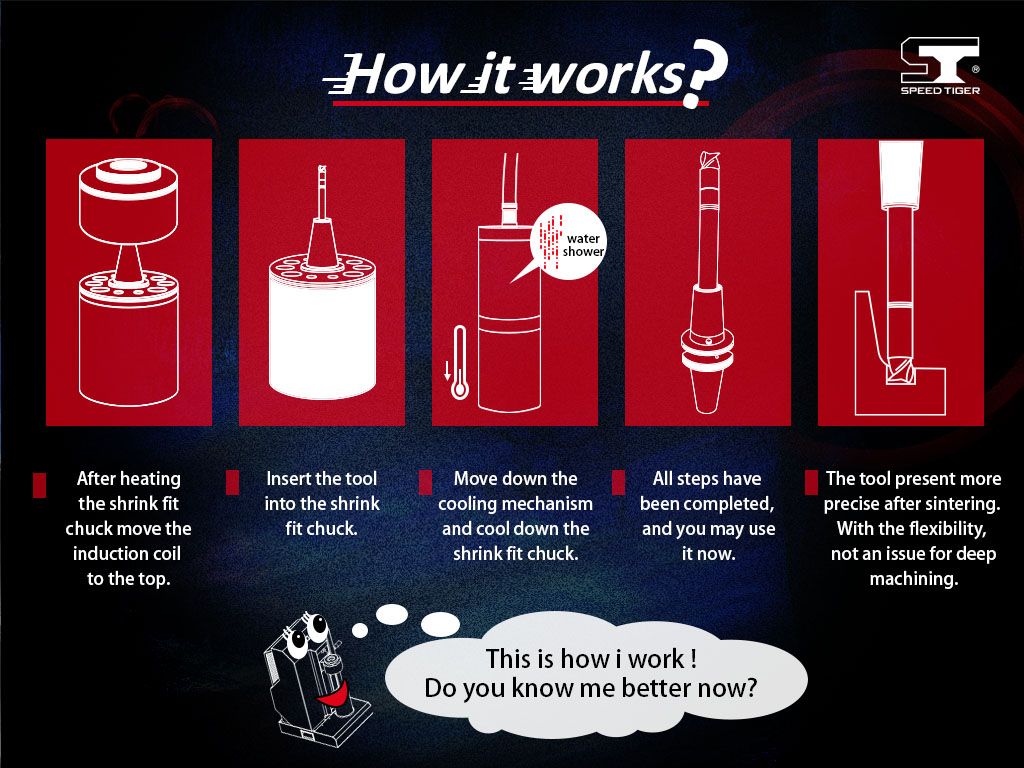

A shrink-fit machine uses high-frequency induction heating and the thermal expansion-contraction principle to securely join cutting tools with tool holders.Its working principle involves generating a powerful magnetic field through high-frequency currents to heat the shrink-fit tool holder, causing its inner bore to expand, making it easy to insert the cutting tool. After insertion, the tool holder rapidly cools and contracts, tightly clamping the tool, and forming a single, integrated sintered tool holder.

Three Major Benefits of Using a Shrink-fit Machine

1. Extended Tool Life

Testing shows that tool life increases by an average of 60% when using sintered tool holders compared to collet tool holders.This is because shrink-fit tool holders maintain consistent runout accuracy, balance quality, and taper precision when changing tools.

2. Reduced Machining Time

Compared to collet tool holders, shrink-fit tool holders reduce average machining time by 7.5%.3. Lower Total Costs & Faster ROI

Although the initial cost of shrink-fit tool holders is higher than collet tool holders, the extended tool life and reduced machining time allow for a return on investment (ROI) within just 5 to 7 months!Comparison of Shrink-fit Tool Holders: Pros and Cons

Advantages of Shrink-fit Tool Holders:

- High Clamping Force: High-frequency heating ensures a strong and secure connection between the tool and holder, preventing loosening—ideal for high-speed, high-force machining.

- High Precision: Shrink-fit tool assemblies offer superior accuracy, improving machining quality.

- Longer Tool Life: Reduces the risk of tool slippage, extending tool lifespan.

- Wide Compatibility: Suitable for various tools and holder materials.

- Fast and Convenient: The sintering process is quick and easy to operate.

Disadvantages of Shrink-fit Tool Holders:

- Equipment Investment: The shrink-fit machine requires a higher initial investment.

- Tool Replacement: Re-sintering is necessary when changing tools.

- Heat Impact: High-temperature sintering may affect certain tool materials.

Shrink-fit Toolholders vs. Collet Toolholders Comparison

Shrink-fit Toolholders are suitable for high-precision, high-efficiency, and high-stability processing requirements, while collet Toolholders are suitable for general processing.| Feature | Shrink Fit Tool Holder | Collet Tool Holder |

| 1. Clamping Method | High-frequency heating & shrink fit | Mechanical clamping |

| 2. Clamping Force | Strong | Relatively weaker |

| 3. Precision High Standard | High | Standard |

| 4. Tool Holder Lifespan | Long | Relatively shorter |

| 5. Application | High-speed cutting, heavy cutting | General cutting |

| 6. Tool Replacement | Requires re-sintering | More convenient |

How to Smartly Choose a Shrink-fit Machine?

When selecting a shrink-fit machine, consider these six key factors to make an informed purchase:- Power Output – Choose a shrink-fit machine with the appropriate power level based on the size and material of your cutting tools.

- Frequency – Higher frequency machines offer faster heating and greater efficiency.

- Precision – A high-precision shrink-fit machine ensures the accuracy of the tool assembly.

- Automation Level – Machines with higher automation are easier to operate and improve efficiency.

- Safety Features – Opt for a shrink-fit machine with built-in safety protections.

- Brand Reputation – Choosing a well-known brand ensures better quality and reliability.

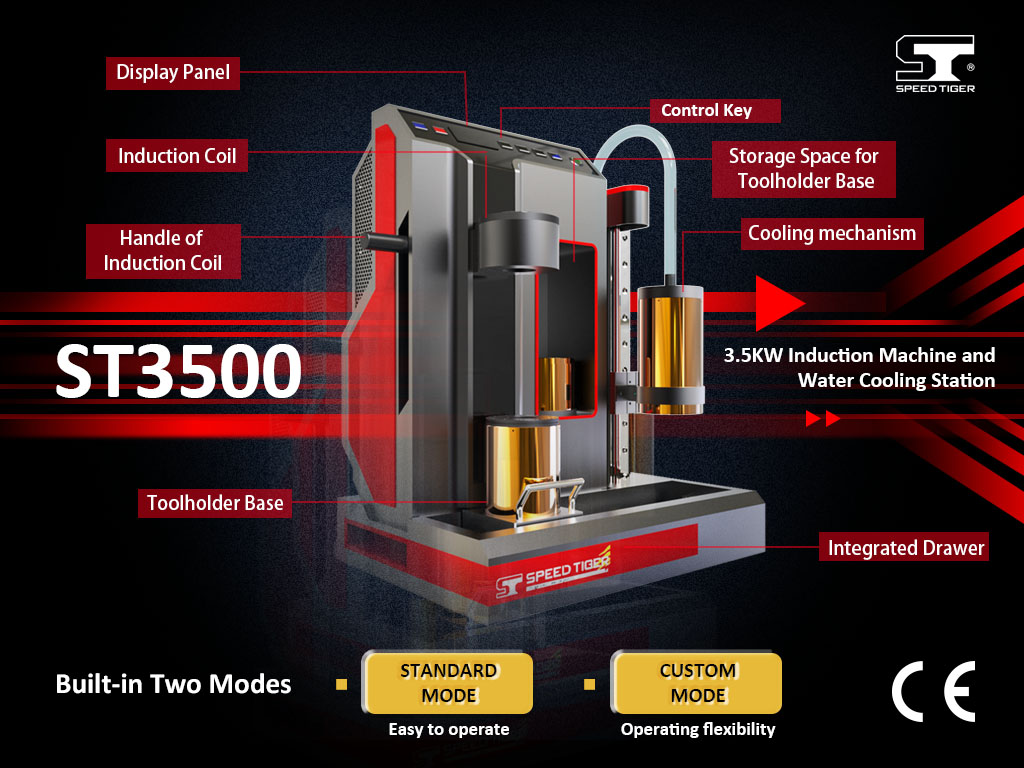

Recommended Shrink-fit Machine – ST3500

The ST3500 is a 3.5KW electromagnetic induction heating water-cooled unit, designed for sintering tungsten carbide tools with diameters ranging from 3mm to 32mm. Its advanced design enhances tool life and enables easy tool loading and unloading through its water-cooling system.

ST-3500 Product Features

- Utilizes a 3.5KW high-frequency heating coil to generate an alternating electromagnetic field.

- Low-power heating and water-cooling design extend the lifespan of the tool holder.

- Water-cooling system helps clean carbon buildup and prevents tool holder rust.

- In standard mode, the sintering time is preset based on the tool holder's inner diameter and actual test results.

- Custom mode allows users to adjust the sintering time according to their needs and automatically records the last operation setting.

ST-3500 Product Advantages

- Fast and Easy Operation – Simply set the diameter and heating time to install or remove tools effortlessly, completing the process in under one minute.

- Extended Tool Life – The low-power heating and water-cooling system helps prevent tool holders from overheating and rusting.

- Two Operating Modes – Standard mode provides preset sintering times, while custom mode allows users to adjust settings based on their specific requirements.

ST3500 Main Applications & How to Use

- Sintering tungsten carbide tools and solid carbide cutting tools.

- Ideal for machining applications that require frequent tool changes, such as mold manufacturing and precision machining.

FAQs: Shrink-fit Machines & Shrink Fit Tool Holders

Q1: Are shrink-fit tool holders suitable for small-diameter tools?

A1: Yes! Small-diameter tools are well-suited for shrink-fit tool holders. If the tool shank is small, a heating-cooling adapter sleeve can be used with a mini shrink fit tool holder for sintering. During cooling, simply place a standard cooling sleeve (Ø6-8mm) over the adapter sleeve to prevent overheating and extend tool holder life. This method is ideal for industries requiring high-precision machining, such as mold making, medical, and precision machinery.Q2: Can a shrink-fit machine be used for all cutting tools?

A2: Not all cutting tools are suitable for sintering. Some materials may deform or become damaged at high temperatures, making them incompatible with the process. Additionally, excessive heat may damage the tool coating, affecting performance, so it's important to check before sintering. Furthermore, shrink-fit machines are primarily designed for cylindrical shank tools—non-cylindrical or highly complex tool shapes may not achieve proper clamping and should not be used.| About Speed Tiger |

Speed Tiger is a professional manufacturer of Carbide Cutting Tools and offers OEM Services, having rich experience in producing carbide-cutting tools and processing consultants for more than 24 years.

Established in 1998, Speed Tiger specialized in the production of precision carbide end mills, drills, turning tools, thread mills, and other tungsten carbide steel customized cutting tools. Speed Tiger crafts cutting tools at extreme nanometer precision +-2㎛ to the exact, enabling to achieve professional cutting quality.

Visit our shop to find out more, or check out our solution to continue learning.

OTHER SOLUTIONS

-

Master Guide of CNC Milling: Process & Application Posted 2023-06-07