The Beginners Guide of CNC End Mill

If you are new to CNC processing, you may think that…

There are so many end mills in the catalog, what’s the difference? And which end mill should I use on my CNC machine?

You will learn the basic knowledge of CNC end mill:

First, we need to know, what is CNC End Mill for?

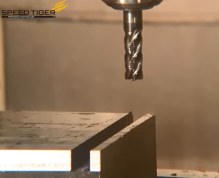

Simply put, End Mill is one kind of milling cutter to do the process of removing metal by CNC Milling machines.

There are various diameters, flutes, lengths, and shapes to choose from. Basically, users choose them according to the material of the workpiece and the surface finish required for the workpiece.

So, let's start by introducing the appearance of the End Mill, including the shapes, flutes, geometry, and coating.

1. End Mill Shapes

Speed Tiger provides other shapes End Mill, visit hight performance Solid Carbide End Mills & Cutters Tools.A. Square End Mill:

Also known as a "flat end mill," this is the most common type and can be used for a variety of milling applications, including side milling, profiling, and plunge cutting. Speed Tiger also offers HPC (high-performance cutting) square type with a little chamfer for better slotting, ramping, and can do trochoidal milling.  Related Products: SPEED TIGER Square End Mill

Related Products: SPEED TIGER Square End Mill

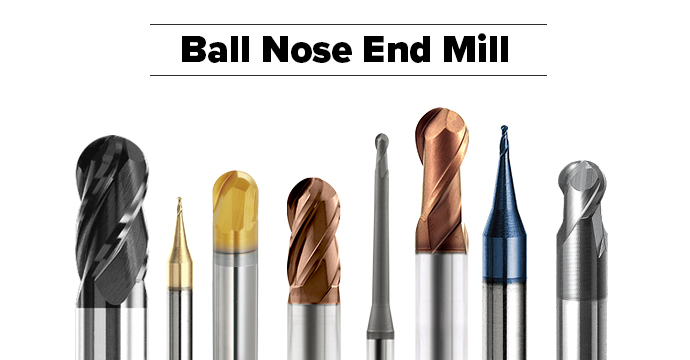

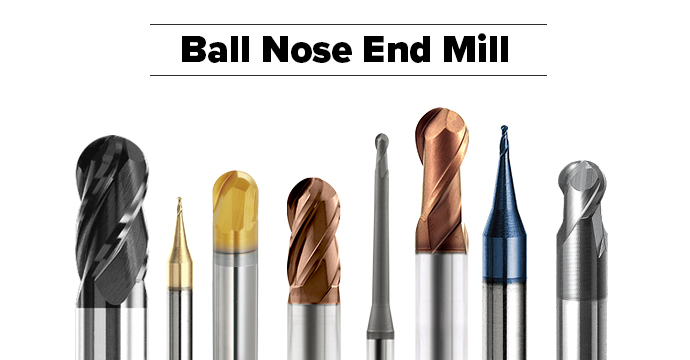

B. Ball Nose End Mill:

The end flute of Ball Nose End Mill is with no flat bottom. It is ground with a full radius equal to half of the tool diameter. For example, you may say 5R to a 10mm ball nose end mill. Ball nose mills are used for contour milling, shallow pocketing, and contouring applications, etc. They are especially good for 3D contouring because they leave a nice rounded edge. Related Products: SPEED TIGER Ball Nose End Mill

Related Products: SPEED TIGER Ball Nose End Mill

C. Corner Radius End Mill:

Imagining there is a radius form at a sharp corner of a square end mill, that's a corner radius milling tool. These are commonly used to mill mold & die as you don’t need to use nearly as many tool changes to get flat-bottom pockets and rounded contours.  Related Products: SPEED TIGER Corner Radius End Mill

Related Products: SPEED TIGER Corner Radius End Mill

D. Taper End Mills:

Also known as pencil end mills and conical end mills, these names are used for describing the shape of its flute. They can produce grooves, holes, or side-milling with a slope angle. Related Products: SPEED TIGER Taper End Mill

Related Products: SPEED TIGER Taper End Mill

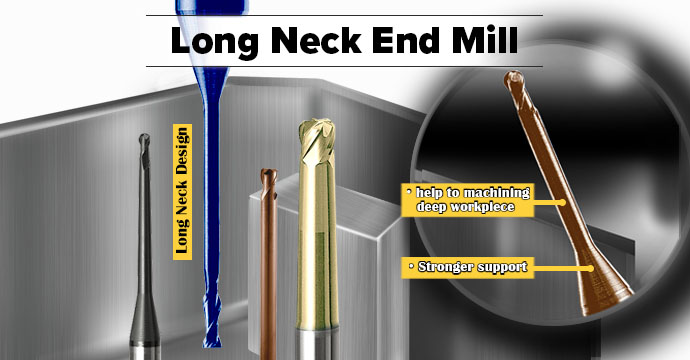

E. Long Neck End Mill:

The design can avoid the interference between the tool and workpiece by reducing the shank diameter behind the flute, which is ideal for deep slotting (deep pocketing).

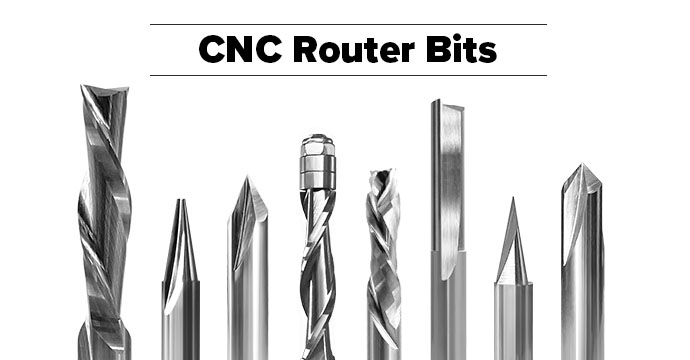

F. CNC Router Bits:

CNC router bits are the cutting tools that work on a CNC router. They usually can be made to cut non-ferrous metals (soft materials), such as aluminum, brass, copper, MDF, plastic, PVC, wood, and more.

Related Products: SPEED TIGER CNC Router Bits

2. End Mill Flutes

Which part is the flute?

The answer is the spiral channels on an end mill. And the design of the flute also will determine which materials you can cut.

The most common options are 2, 3, or 4 flutes. Generally, fewer flutes mean better chip evacuation, but at the expense of surface finish. More flutes give you a nicer surface finish, but worse chip removal.

Table of end mills flutes number

- The different performances of different numbers of flutes.

|

Number of Flutes |

1 flute |

2 flutes |

3 flutes |

4 flutes |

6 flutes |

|

Rigidity |

Poor |

Fair |

Average |

Good |

Excellent |

|

Chip evacuation |

Excellent |

Excellent |

Good |

Fair |

Poor |

|

Wear time |

Poor |

Fair |

Average |

Good |

Excellent |

|

Vertical accuracy |

Poor |

Fair |

Average |

Good |

Excellent |

|

Surface roughness |

Poor |

Fair |

Average |

Good |

Excellent |

|

Performance on the soft material workpiece |

Excellent |

Excellent |

Good |

Fair |

Poor |

|

Performance on the hard material workpiece |

Poor |

Fair |

Average |

Good |

Excellent |

|

Performance on grooving/ slotting |

Poor |

Fair |

Average |

Good |

Excellent |

|

Performance on side milling |

Poor |

Fair |

Average |

Good |

Excellent |

- The effect of helix angle:

|

Helix Angle |

Helix Angle 15° |

Helix Angle 35° |

Helix Angle 45° |

Helix Angle 55° |

|

Surface roughness |

Fair |

Good |

Excellent |

Excellent |

|

Surface fluctuation |

Excellent |

Good |

Fair |

Fair |

|

Chip removal |

Excellent |

Good |

Fair |

Fair |

|

Cutting torque |

|

|

|

|

|

Axial tension |

|

|

|

|

|

OD wear |

|

|

|

|

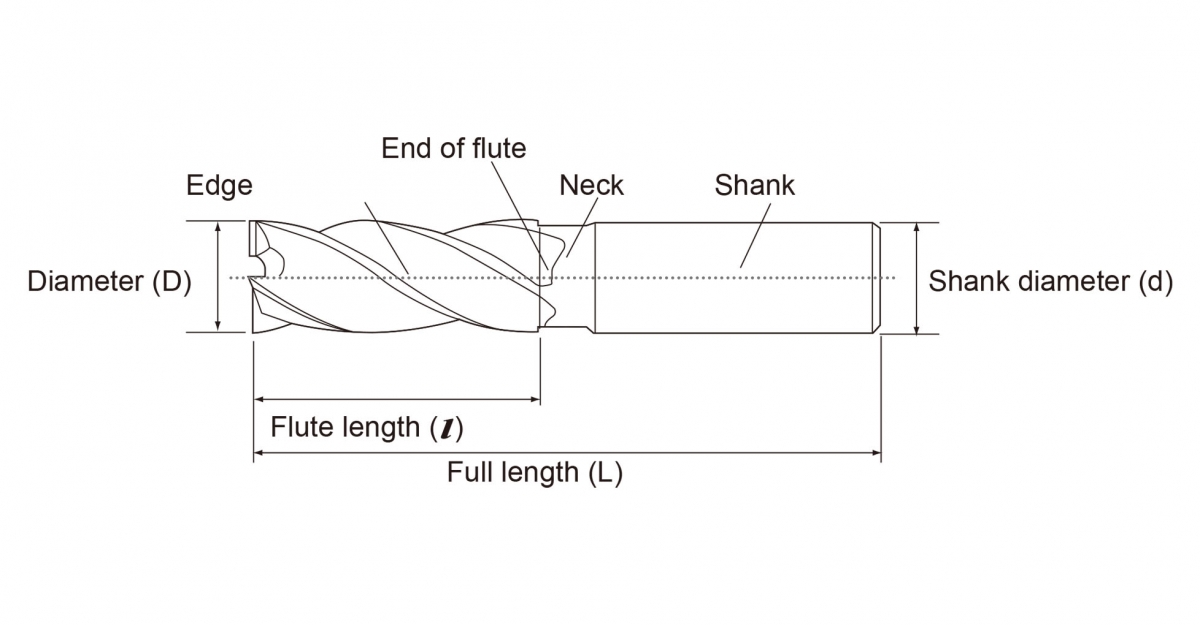

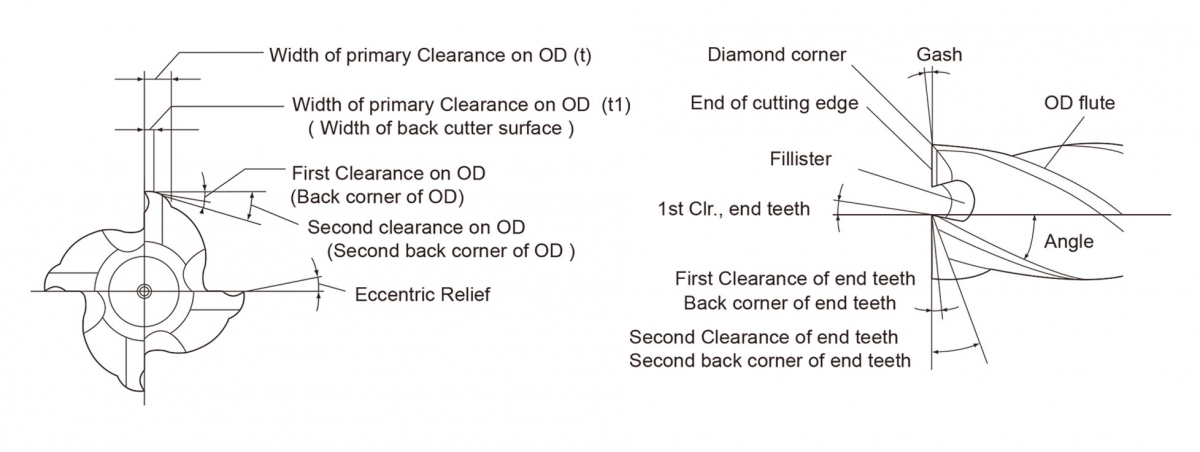

3. Detail of the end mill

*SIDE VIEW of the end mill.

*SIDE VIEW of the end mill. *TOP VIEW of the end mill & EDGE of the end mill.

*TOP VIEW of the end mill & EDGE of the end mill.Related Article: End Mill Size Standards Chart & Information

4. End Mill Coatings

What does coating do?

Coating is like the clothes of an end mill. On different occasions, it needs to be worn the right clothes. For example, people need to wear a spacesuit when they are in outer space, and a swimsuit when they swim. Therefore, depending on your processing conditions, it will affect what coating you need to choose.

Basically, there are 2 kinds of thin film deposition, Physical Vapor Deposition (PVD), and Chemical Vapor Deposition (CVD). You may read more detailed coating information will in "End Mills need Coatings".

| Related Products Info: |

Square End Mill: also known as a "flat end mill". The flutes are with sharp corners that are squared off at a 90° angle. They are the most popular and general milling cutters.

Square End Mill: also known as a "flat end mill". The flutes are with sharp corners that are squared off at a 90° angle. They are the most popular and general milling cutters. Ball Nose End Mill: It is ground with a full radius equal to half of the tool diameter. For example, you may say 5R to a 10mm ball nose end mill.

Ball Nose End Mill: It is ground with a full radius equal to half of the tool diameter. For example, you may say 5R to a 10mm ball nose end mill. Corner Radius End Mill: There is a radius form at a sharp corner of the square end mill, that's a corner radius milling tool.

Corner Radius End Mill: There is a radius form at a sharp corner of the square end mill, that's a corner radius milling tool. Taper End Mill, pencil end mills, or conical end mills, these names are used to describe the shape of its flute. They can produce grooves, holes, or side-milling with a slope angle.

Taper End Mill, pencil end mills, or conical end mills, these names are used to describe the shape of its flute. They can produce grooves, holes, or side-milling with a slope angle. 45°, 60°, 90°, 120°chamfer angles; can do top chamfer and bottom chamfer.

45°, 60°, 90°, 120°chamfer angles; can do top chamfer and bottom chamfer. Aluminum Application Experts: Aluminum alloy is one of the exotic materials because the chips can stick to the flutes and pack, and Speed Tiger designed a series of Aluminum End Mill to meet many kinds of processing demands.

Aluminum Application Experts: Aluminum alloy is one of the exotic materials because the chips can stick to the flutes and pack, and Speed Tiger designed a series of Aluminum End Mill to meet many kinds of processing demands.■ More Information & Tips about CNC End Mill:

Related Article: The Guide of End Mill for Aluminum Machining.

Application: Excellent cutting is reached in machining non-ferrous materials, especially in aluminum with over six multiple in machining efficiency. Long tool life and precision machining in PCB boards, Brass, Titanium, Ceramics, Fiberglass, etc.

Related Article: The Basic(But Complete) Guide of CNC Router Bits

What are CNC router bits and what should you know about them? This can be a complex topic that throws up lots of additional questions, and it’s easy to get bogged down if you’re a beginner. So, we have created this basic (but complete) guide that tells you everything you need to know about CNC router bits in this article.

Related Article: Master Guide of CNC Milling: Process & Application

If you are new to CNC milling, you have probably heard of this term but be unsure what it means. In this article, you will find all the information you will need to understand what CNC milling is, how it works, its applications, advantages, and more. Read on to discover everything you need to know about CNC milling.

Related Article: Master Guide of Roughing & Finishing Cut in Machining (Differences & Usage)

Machining or cutting consists of a number of stages, taking a raw piece of material from its initial state to the desired object that it is intended to be. Multiple techniques are used to obtain the final result to ensure it is the right shape and size and has the right finishing. The processes used consist of categories such as conventional machining, abrasive cutting, micro-precision machining, and non-traditional machining. Two of the initial stages in machining are the rough cut and finishing cut, which shape the material and improve the finish of the surface. Both of these are important processes but it's important to understand the differences between them and when each one should be used.

Related Article: End Mill Cutting & End Milling - Technical Guide

End mills are a key tool for cutting, with a range of different applications. As one of the most common types of cutting tools, end mills are also unique and specifically used for the end milling process. End mill cutting and end milling are crucial in manufacturing, and being familiar with these processes and tools is a must.

Related Article: The Guide to Buying Carbide Drill Bits, Choose the right one for your job!

If you work in an industry that relies on tools to get the job done, you’ll already know just how important a drill is for your overall success, and we’ve put together a handy carbide drill bits buying guide, so you can know exactly what piece you need for the job!

If you have any questions or needs, please feel free to contact us!

OR Custom End Mill for your project!

SEND US AN INQUIRY :)

Speed Tiger is the leading Carbide End mills manufacturer in Taiwan, we provide a large range of CNC End mills, see more end mills products here.

| About Speed Tiger |

Speed Tiger is a professional manufacturer of Carbide Cutting Tools and offers OEM Services, having rich experience in producing carbide cutting tools and processing consultants for more than 24 years.

Established in 1998, Speed Tiger specialized in the production of precision carbide end mills, drills, turning tools, thread mills, and other tungsten carbide steel customized cutting tools. Speed Tiger crafts cutting tools at extreme nanometer precision +-2㎛ to the exact, enabling to achieve professional cutting quality.

Visit our shop to find out more, or check out our solution to continue learning.

OTHER SOLUTIONS

-

Master Guide of CNC Milling: Process & Application Posted 2023-06-07