PRODUCTS

400PLUS - High Efficient General Series

Product Number:P-UMIE, P-UET, P-ULET, P-UVT, P-ULVT,P-ULNT, P-UMIB, P-UBT, P-ULBT, P-UBTSX, P-ULBTS, P-ULBTM, P-ULBTL, P-ULNBT, P-UPBT,

█Feature: ①Ultra Fine Micro Grain Carbide raw material with the most suitable flute geometry ensure to improve chip disposal and rigidity.②HIGH PERFORMANCE - Unequal flute spacing and irregular helix flutes ensure stable machining of difficult-to-cut materials and higher efficiency. ③ANTI-VIBRATION, LESS CHATTER, REDUCED BURRING - Vibration absorption provides stability, high-efficiency finishing, and improved chip disposal.

█Application: ~HRC55/ Iron, Carbon steel, Cast Iron, Alloy Steel, Tool Steel, Heat treatment Steel, Welding Steel

-

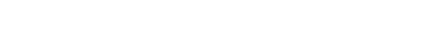

Features

- Strong edge to prevent chipping at corners.

- Unequal Flute Spacing,A≠B Irregular Helix Flutes, α≠β Ensures stable machining of difficult-to-cut-materials, and achieve high efficient performance.

- Tool diameter tolerance 0~-0.02mm.

- Special flute geometry to improve chip disposal.

- Superior wear and chipping resistance due to optimally matched coating and carbide material.

✓ Exellent vibrant absorption provides stability.

✓ Less chatter and high effieciency finishing.

✓ Reduce metal burr when machining.

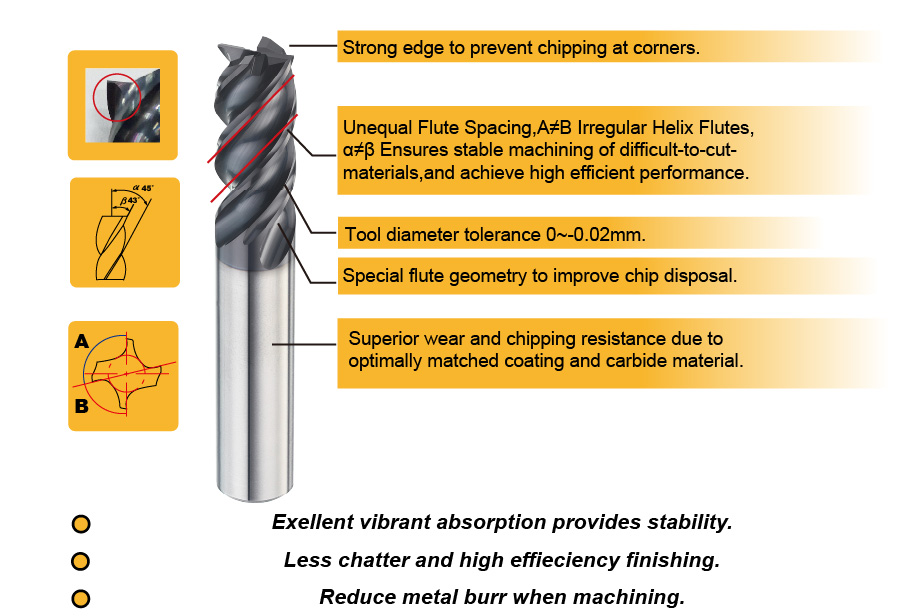

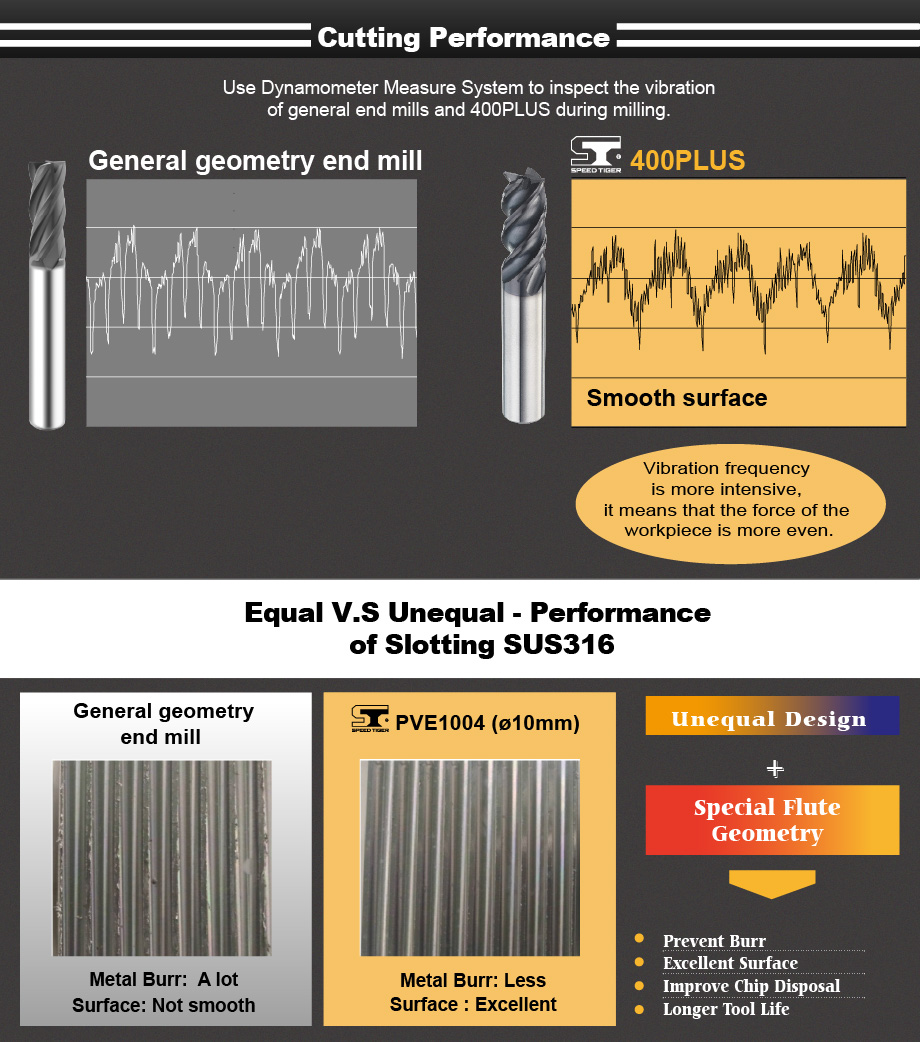

Unequal Design + Special Flute Geometry- Prevent Burr

- Excellent Surface

- Improve Chip Disposal

- Longer Tool Life

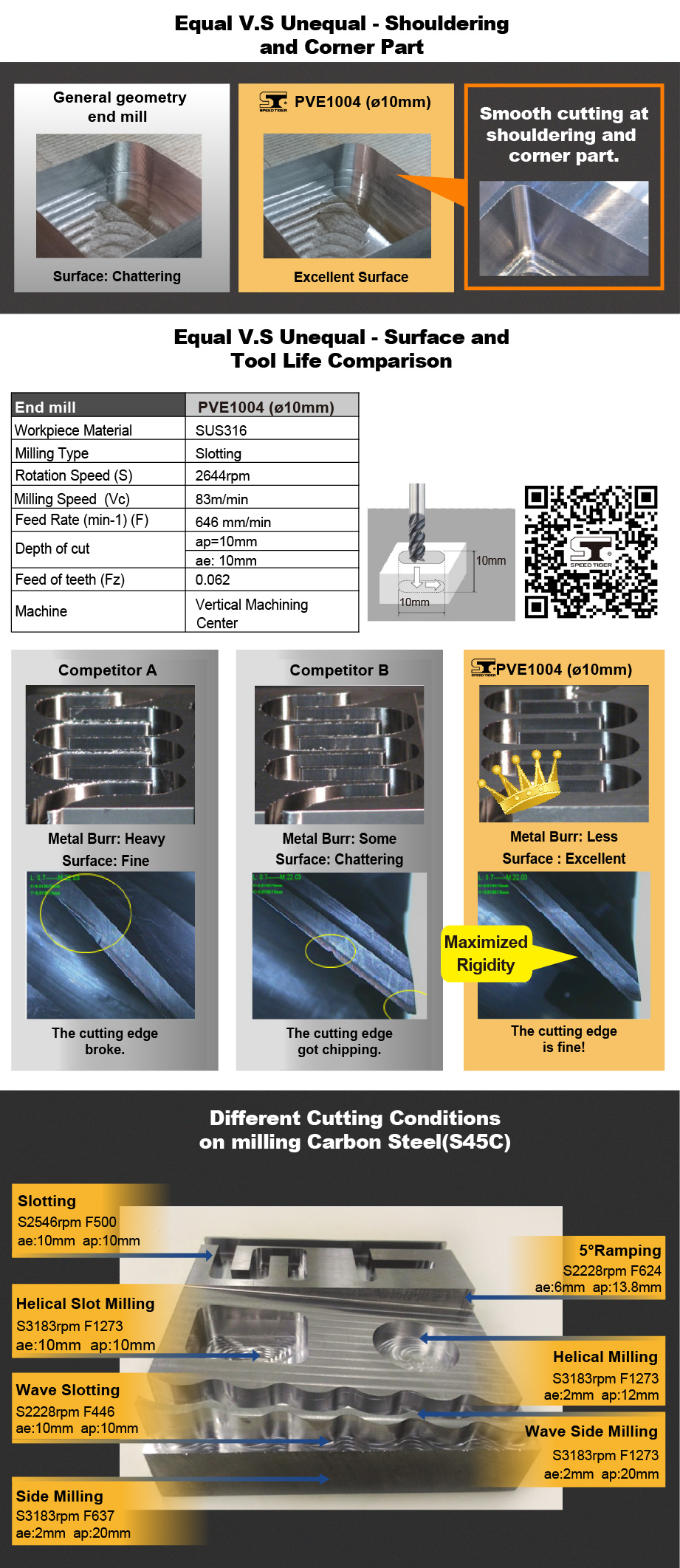

Different Cutting Condition on milling Carbon Seel (S45C)- Slotting

- Helical Slot Milling

- Wave Slotting

- Side Milling

- 5°Ramping

- Helical Milling

- Wave Side Milling

Comparison Series Grain Size Hardness

(HRC)Coating Application 200 Nano 0.2μm ~65 TiSiN Super Hard Hardness 400 Nano 0.4μm ~60 nBS High Hardness 600 Nano 0.6μm ~50 AlTiN General -

ALTIBN Coating

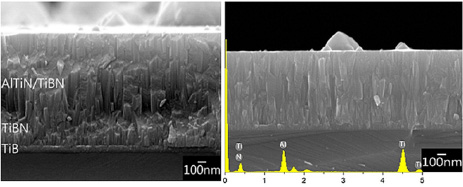

Coating Structural Analysis-SEM

Normal Temperature Mechanical Analysis

In normal temperature mechanical analysis,the performance of AlTiBN is superior to AlTiN in hardness, wear rate and coating roughness.Hardness (Hv) Impact of Diameter Lc2-Lc1 Wear Rate Roughness (µm) AlTiN 3672 305(um) 8.28N 6.49x10-6 0.233 AlTiBN 4088 280.9(um) 17.6N 5.11x10-6 0.166

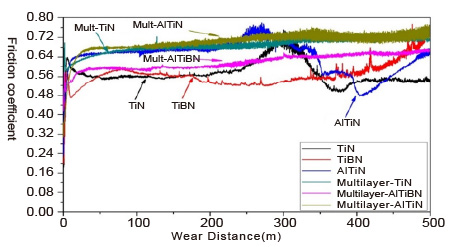

The Oxidation Wear of 700°C

Fiction Coefficient Wear Distance Wear rate TiN 0.5662 316.3 6.4x10-6 TiBN 0.5664 281.2 5.69x10-6 AlTiN 0.6402 281.4 4.97x10-6 Multi-TiN 0.686 277.4 4.82x10-6 ALTIBN 0.618 281.8 4.66x10-6 Mult-ALTiN 0.7014 290.1 5.5x10-6

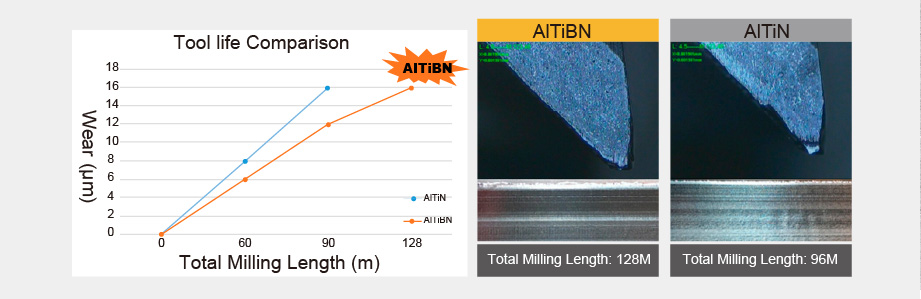

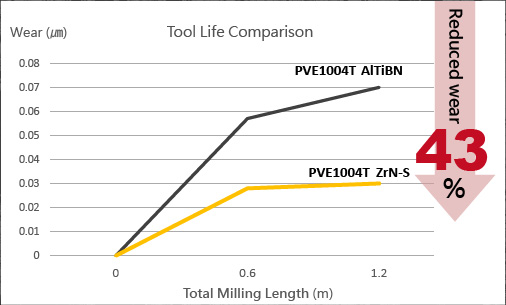

Tool Life Comparison and Cutting Edges

Milling Type Side Milling Feed Rate 1082mm/min Work Piece S45C Depth of Cut ap=20 ae=1.2 Tool Size 10mm x 30 x 75L Coolant Way Air Rotation Speed 3183 rpm CNC Machine CNC YCM FV102A ZrN-S Coating

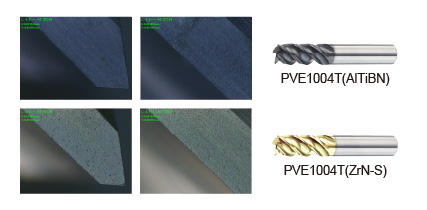

Block resistance- Suitable for High Speed machining with both dry and wet cutting way.

- Hardness 2800~3000 HV

- Coefficient of friction: 0.3

- Oxidation Temp: 800~900°C

- High performance coating(Light golden)

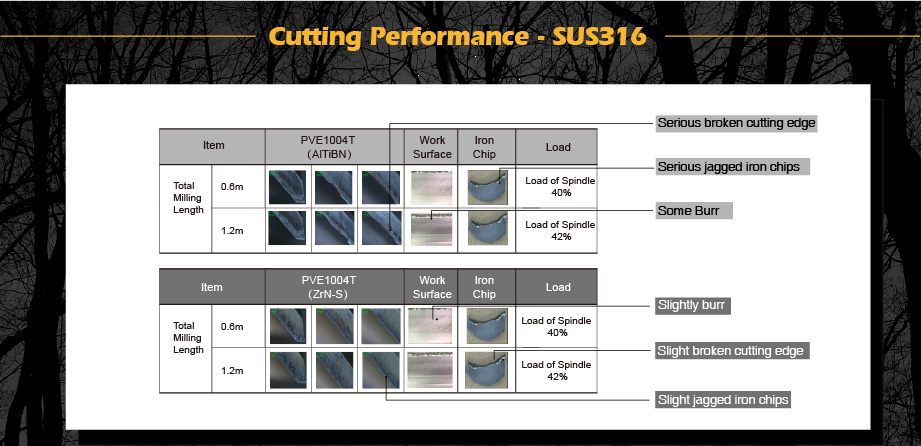

Measured comparison-SUS316

Before the tool is used

Parameter Tool(Coating) PVE 1004 ZrN-S Cutting Material SUS316 Rotation Speed (S) 2644 rpm Milling Speed (Vc) 100 m/min Feed Rate (F) 646 mm/min Depth of cut ap=10mm / ae=10mm (Fz) Feed of teeth 0.062 Machine YCM FV102A Holder BT40 Shrink fit holder The length of Tool Extend 37mm Cooling Way Water

Parameter Tool(Coating) PVE 1004 ZrN-S Cutting Material SUS316 Rotation Speed (S) 2644 rpm Milling Speed (Vc) 100 m/min Feed Rate (F) 646 mm/min Depth of cut ap=10mm / ae=10mm (Fz) Feed of teeth 0.062 Machine YCM FV102A Holder BT40 Shrink fit holder The length of Tool Extend 37mm Cooling Way Water

Coating Total Milling Length (m) 0.6m 1.2m ALTIBN 0.057µm 0.07µm ZrN-S 0.0µm 0.03µm

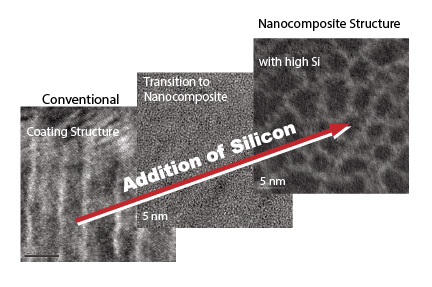

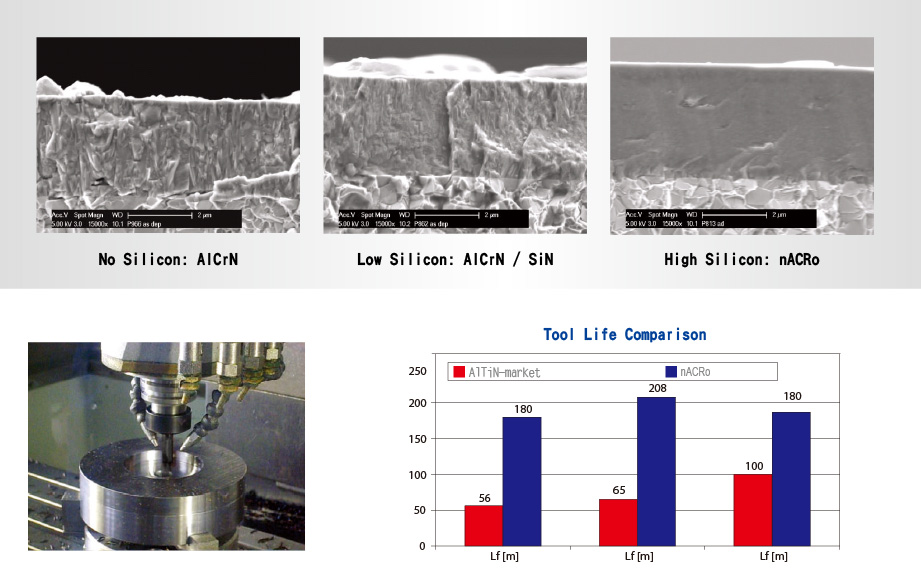

nACRo Coating  nACRo Nanocomposite coating processBy deposition very different kinds of materials,the components (like Ti, Cr, Al in the first group,and Si in the other) are not mixed completely, and 2 phases are created. The nanocrystalline TiAlN- or AlCrN-grains become embedded in theamorphous SiN-matrix and the nano-composite structure develops.

nACRo Nanocomposite coating processBy deposition very different kinds of materials,the components (like Ti, Cr, Al in the first group,and Si in the other) are not mixed completely, and 2 phases are created. The nanocrystalline TiAlN- or AlCrN-grains become embedded in theamorphous SiN-matrix and the nano-composite structure develops.

Silicon increases the thoughness and decreases the internal residual stress of the coating. The increasing of the hardness is generated by the structure only, the SiN matrix enwraps the hard grains and avoids growing of their size.

- Contain Si membrane, oxidation start temperature : 1,100℃.

- Nano grade coating, better surface finish

- Extremely high nano hardness, extremely high adhesion.

- Better protection for tools, reduction of production cost.

Carbide End Mills Ø10mm, z=4, steel 34CrNiMo6 (30 HRC), Coolant: Air; Minimum lubrication

- Tested tools: 2x4 - Source: Carmex, Maalot, ISR -

Specification Download

Cutting Condition DownloadType Mode Flutes Diameter Photo Miniature Square P-UMIE 2 0.2mm~3mm

Square P-UET 2 / 4 1mm~25mm

Long Flute Square Type P-ULET 2 / 4 2Flutes-1mm~16mm

4Flutes-1mm~25mm

Multiple Flutes Square Type P-UVT 5/7/9 5Flutes-6mm,7Flutes-8mm~12mm,9Flutes-16mm~25mm

Multiple Flutes Long Flute Square Type P-ULVT 5 / 7 / 9 5Flutes-6mm

7Flutes-8mm~12mm

9Flutes-16mm~25mm

Long Neck Square Type P-ULNT 2 / 3 2Flutes-0.5mm~2mm

3Flutes-2mm~4mm

Miniature Ball Nose Type P-UMIB 2 0.3mm~3mm

Ball Nose Type P-UBT 2 / 4 2Flutes-1mm~25mm

4Flutes-2mm~25mm

Long Shank Ball Nose Type P-ULBT 4 6mm~16mm

Power Short Flute Ball Nose Type P-UBTSX 2 1mm~16mm

Long Shank Ball Nose Type P-ULBTS,P-ULBTM,P-ULBTL 2 1mm~25mm

Long Neck Ball Nose Type P-ULNBT 2 0.5mm~4mm

Pencil Neck Ball Nose Type P-UPBT 2 1mm~10mm

Pencil Long Neck Ball Nose Type P-ULPBT 2 2mm~4mm

Corner Radius Type P-URTA 2 / 4 2Flutes-1mm~12mm

4Flutes-3mm~12mm

Pencil Neck Corner Radius Type P-UCRS 2 / 4 2Flutes-1mm~16mm

4Flutes-2mm~12mm

Long Neck Corner Radius Nose Type P-UCR 4 6mm~12mm

Square Type PVE 4 3mm~25mm

Square Type Short Flute PVES 4 6mm~20mm

Square Type Medium Flute PVEM 4 6mm~20mm

Square Type Long Flute PVEL 4 6mm~20mm

Square Type Heavy Duty PVEC 4 6mm~20mm

Ball Nose Type PVB 4 6mm~16mm

Ball Nose Type Long Flute & Neck PVBSX 4 6mm~16mm

Corner Radius Type PVR 4 3mm~25mm

-

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No. 9, Gongyequ 35th Rd., Xitun Dist., Taichung City 407021, Taiwan (R.O.C.)

Worldwide Sales Network

Worldwide Sales Network

● Social Media